Our Services

We provide spare and service to our esteem clients with best suited alternatives at minimum cost.

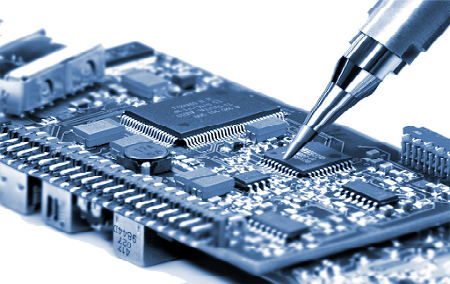

Repairing

Our in-house component and card level repair facility helps our customers keep their manufacturing line up and running. This service not only results in cost savings but also saves customers the time involved in procuring new products. Through our expertise in component level repairs of all power electronics we are able to offer highly efficient and quick repairs service. We repair a majority of the VFD's (AC Drives) including Delta, Allen Bradley, Mitsubishi, Siemens, Omron, Wacon, Fuji-Electric, Schneider Electric, Panasonic, Pro-Face, ABB, Yaskawa, Hitachi, L&T etc.

- In-house repair facility

- Calibrated test equipment

- In-house load testing (Simulation)

- Spare cards stock of Delta, Schneider, Fuji

- Experienced team of engineers

- Warranty after repairs

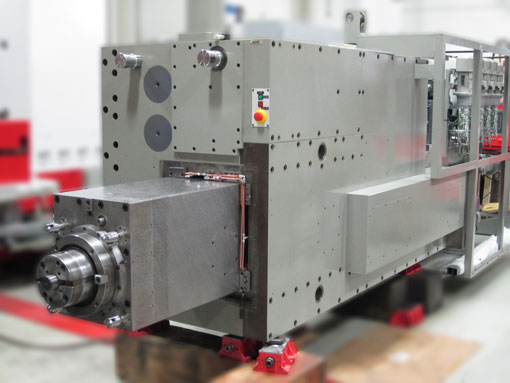

Retro Fit- Reconditioning

EMP’s experts can recondition machinery and equipment made by any manufacturer. We offer a range of upgrade and expansion packages, ranging from a basic service to full reconditioning to the latest specifications – naturally, all tailored to your specific needs. EMP retrofit packages are available for machinery from any manufacturer. Proven, reliable and affordable, they represent an investment in your future with a guaranteed return.

System Integration

- Customized Hardware & Software Selection.

- Preparation Of Configuration Drawings And Control Philosophy.

- Third Party Devices Integration And Testing.

- Driver Development For Third Party Device

- System Functional Testing As Per The Customer Requirement.

- Inspection By The Customer And Final Acceptance Test.

Control panel Manufacturing

- PLC Control Panel

- Drive Panel

- Instrumentation panel

- Electrical panel

- Panel for IPC/ SCADA systems

- Assembly of components in the Panel as per the approved drawing.

- Wiring of the components as per the approved drawings.

- Testing of the panel as per the standard procedures.

AMC- PLC,SCADA,HT/LT Brakers

Annual maintenance contracts with the company and give as many visits as per requirement of customer for rectification, with the help of this routine check of all the automation products are done periodically.

PLC/HMI- Programming & Development

PLC Programming Software, Ladder Logic and HMI Software Development For All PLC, HMI Programming Software. Scada Configuration, Plan And Preparation Of Flowcharts And Algorithms For Control Philosophy. Technical Assistance To The Customer In The Installation And Commissioning Of Scope Of Work. Installation And Commissioning Of The System To The Satisfaction Of The Customer. Preparation Of General Arrangement Drawings, Loop Diagrams And Interconnection Diagrams Using Auto CAD Software. Documentation & Maintenance Manual Of The System